Water and sewage pumping stations | water pumping station

In catchment systems where there is no possibility of gravitational drainage of the medium and it is necessary to raise them to a higher level, water pumping stations and sewage pumping stations type NAVO by NavoTech. These solutions are also called as water pumping station.

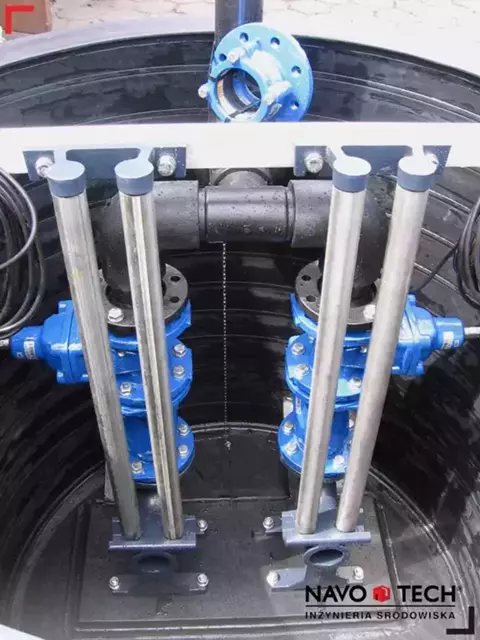

Water pumping stations NavoTech operate in the flow range from the smallest (where the lower limit is limited by the flow rate in the discharge pipeline) to several hundred l/s. Pumping stations operate as two-, three- and even four-pump systems, with the highest flows installed in two tanks acting as a system of communicating vessels. All materials used in the pumping station are adapted to work in aggressive environments.

Selection of pumping stations, water pumping stations and equipment is carried out individually according to the needs of the project and the customer's requirements by the NavoTech Technical Department. This approach is aimed at preparing an offer that meets your needs and requirements, and at the same time is adapted to the field conditions, applicable health and safety regulations and industry agreements.

Water pumping stations and sewage pumping stations are a complete pumping unit delivered in its entirety to the place of installation, we perform assembly and technological start-ups. As part of our orders, we offer and we implement service contracts pumping station.

Water pumping station and sewage pumping station solutions proposed by NavoTech:

- NAVO/B in a concrete tank, concrete min. C35/45,

- NAVO/PE in a polyethylene tank, stiffness min. SN4.

Water and sewage pumping stations

- Water pumping station and sewage pumping station - CONSTRUCTION

- Water pumping station - sewage pumping station - CONTROL

In terms of equipment quality and operational reliability, NavoTech does not compromise and therefore uses only selected and tested materials in terms of their performance and chemical resistance.

NavoTech equips water pumping stations with pumps from the largest Western manufacturers: Grundfos, Lowara, KSB, ABS, as well as Polish: Metalchem Warszawa, Meprozet Brzeg.

Reinforced concrete pumping station tanks NAVO/B are manufactured on the basis of C35/45 class concrete, W-8 water resistance class and F-150 frost resistance class; they do not corrode in the environment of groundwater and sewage. Intended for installation in green areas or heavily trafficked areas.

Double-walled pumping station tanks NAVO/PE made of polyethylene in the shape of a cylinder with a vertical axis, are made on the basis of double-walled, structural, spiral pipes characterized by high circumferential stiffness, min. SN4, very good abrasion resistance and complete chemical resistance.

As a standard, all tanks are topped with a stainless checker plate cover.

The basic element of the control and automation system is the power supply and control cabinet of the instrumentation and control equipment with optical and sound alarm signaling, installed next to the tank.

It is possible to mount the cabinet inside the building located near the pumping station. The housing of the cabinet is lockable, resistant to weather conditions and provides the required degree of protection IP54. At the customer's request, we offer monitoring by means of, for example, GSM, GPRS mobile telephony, radio signal or cable, informing about the operating states of the pumping station.

INFORMATION MATERIALS

Catalog:Water and sewage pumping stations

Catalog:Water and sewage pumping stations- View online: Navotech – Sewage pumping stations by NavoTech – Issuu

Water pumping stations and sewage pumping stations offered by NavoTech are high-quality and reliable products. Our company does not compromise on equipment, which is why we only use materials selected and tested for their performance and chemical resistance. Pumping stations are equipped with pump the largest producers, such as Grundfos, Lowara, KSB, ABS, as well as Polish: Metalchem Warszawa, Meprozet Brzeg.

Pumping stations are available in two variants: reinforced concrete tanks of the NAVO/B pumping station and double-walled tanks of the NAVO/PE pumping station. Reinforced concrete tanks are manufactured on the basis of C35/45 class concrete, they are watertight, frost-resistant and do not corrode. Double-walled NAVO/PE tanks are made of polyethylene and are characterized by high circumferential stiffness, very good resistance to abrasion and complete chemical resistance.

The basic element of the control and automation system is the power supply and control cabinet of the instrumentation and control equipment with optical and sound alarm signaling, installed next to the tank. It is possible to mount the cabinet inside the building located near the pumping station. At the customer's request, the company offers monitoring via GSM, GPRS, radio signal or cable, informing about the operating status of the pumping station.