Table of Contents:

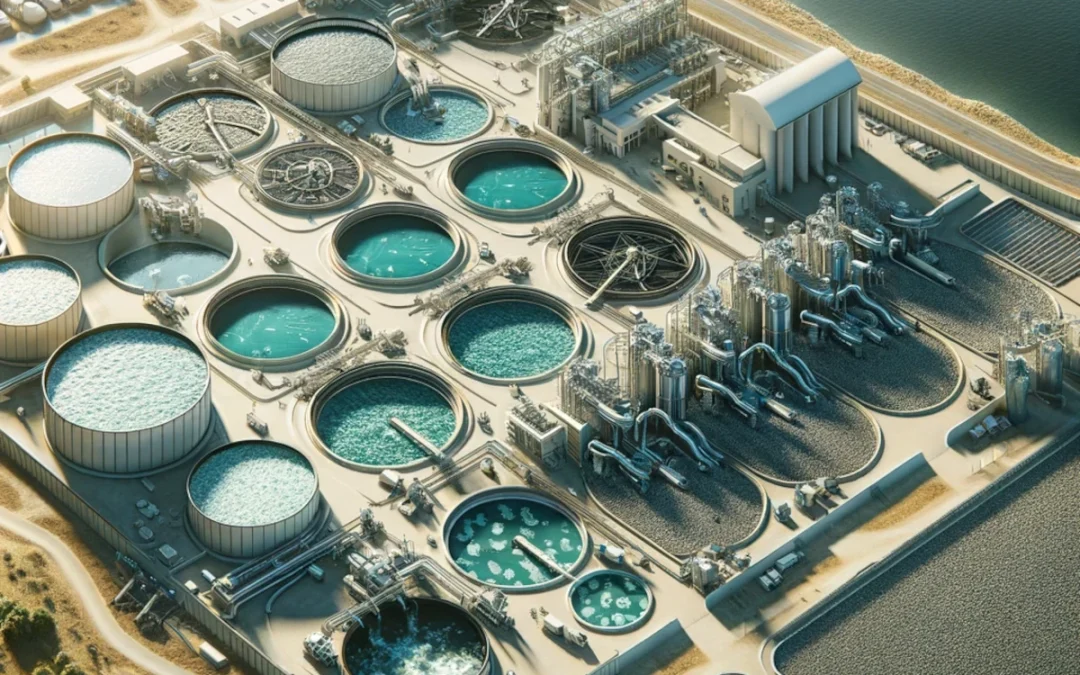

If you are planning to build a property that cannot be connected to the central sewage network, it is necessary to use an alternative solution for wastewater treatment. This action is necessary to safely discharge treated wastewater into local water bodies or drainage systems. The most frequently chosen solution in such cases is to install your own biological sewage treatment plant.

Are you looking for an efficient and Polish-made sewage treatment plant? See our solutions in this area, you will learn more after visiting the website: https://navotech.com.pl/oferta/oczyszczalnie-wody-i-sciekow/

Biological wastewater treatment involves the use of organic and inorganic compounds in sewage by microorganisms to meet basic life needs. Creating optimal conditions for the existence of microorganisms (presence of oxygen, nutrient, mixing, temperature, pH) means that sewage is treated quickly and effectively.

Sewage treatment plant is an advanced system that allows waste from real estate to be processed to a degree that allows it to be safely returned to the water cycle or groundwater resources, without causing harm to the local environment or ecosystem. As you conduct research on this topic, you will quickly notice that there are many different types of treatment plants, each operating on their own unique principles.

Here's an overview of the variety of systems available and the key benefits each brings.

SBR BATCH REACTORS

SBR sewage treatment plants are a classic, proven solution for wastewater treatment for small and large communities. SBR sewage treatment plants are used to neutralize sewage from service facilities (hotels, guesthouses, schools, kindergartens, social welfare homes), housing estates and other groups of buildings. They allow very good removal of suspensions, organic load, phosphorus and nitrogen. A batch reactor (SBR) with low-loaded activated sludge was used as the biological stage. Wastewater treatment takes place in several phases and cycles during the day in one tank. Each treatment stage is designed with great precision, and the modern control system is an innovative, future-proof concept of the wastewater treatment process. Due to the adopted purification technology and design solutions, this device is characterized by low operating costs.

SBR sewage treatment plants meet all stringent environmental protection requirements, which allows it to operate in difficult environmental conditions and in protected areas.

Wastewater treatment using SBR technology is relatively simple and flexible. It allows you to eliminate the instability of biological processes, which may be caused by a sudden change in the composition of sewage, temperature or the inflow of digested sewage. The technological system of the sewage treatment plant may vary depending on the intended purification purpose, project requirements, size of the treatment plant, and equipment used. It is worth paying attention to the lack of technology in question secondary settling tank, whose function is taken over by the batch reactor.

In the first stage, raw sewage is directed to a retention and averaging tank, where it is mixed and homogenized throughout the volume and solids are separated. From the retention tank, sewage is discharged to the SBR biological reactor via a pumping system according to a given technological process.

Sewage treatment plants SBRs are cyclic, batch reactors in which wastewater is subjected to subsequent treatment processes. In the sewage treatment plant system, within one cycle, the following phases alternate: sewage collection, aeration, mixing, sedimentation.

ROTATING DISC BED

Sewage treatment plants built using rotating disc bed technology are intended for local treatment of domestic and commercial sewage from residential buildings and service facilities (hotels, schools, sanatoriums, social facilities of production plants, etc.). It can also be used to purify industrial wastewater from agri-food processing, if its physicochemical properties do not differ significantly from those typical for domestic wastewater.

Low-load rotating disc beds were used as a biological stage. Due to the adopted purification technology and design solutions, this device has very low operating costs (no energy-intensive pressure aeration systems). Sewage treatment plants built using rotating disc bed technology are used especially where there are large unevenness of sewage inflow and interruptions in the operation of the treatment plant. This is due to the high stability of the treatment plant operation regardless of fluctuations in the input parameters. A temporary, several-fold reduction or increase in the amount of sewage flowing into the treatment plant does not, as practice has shown, result in a deterioration of the sewage parameters at the outflow from the treatment plant.

Sewage supplied to the treatment plant is directed to sewage settling tank, fresh water. It removes easily settling suspensions and averages the composition of sewage. The precipitated suspensions fall into the fermentation chamber, where they are thickened and anaerobically stabilized. Then, the mechanically treated sewage flows to the biological stage of the treatment plant - a set of rotating disc beds. Purification processes take place through intensive contact of sewage with the biological film formed on the discs. During the rotation of the bed, this membrane absorbs organic pollutants from the sewage when immersed, and when emerging, it takes in the oxygen needed to remove them. When immersed again, part of the absorbed oxygen passes into the sewage filling the bathtub, supplying the floating, biologically active particles of the membrane.

The wastewater treatment technology used is characterized by a smaller amount of sludge than in the case of conventional activated sludge systems.

ACTIVATED SLUDGE

The activated sludge process, also known as activated sludge, is one of the most common wastewater treatment methods, used both in small domestic installations and in large commercial facilities.

The operation of the sewage treatment plant is based on the principle of a flow reactor with activated sludge, in which biochemical transformations of pollutants take place. This ensures full biological treatment of sewage and stabilization of the resulting sewage sludge. A special feature is the exceptional precision of the technology used. The effect of the treatment plant's operation is to achieve a high level of reduction of pollutants in the treated sewage.

The principle of operation of the sewage treatment plant is relatively simple, which minimizes operational problems. Sewage supplied to the treatment plant is directed to settler preliminary stage, where easy-falling suspensions and floating materials are removed. Initial sedimentation in settler removes suspensions including BOD5. Sewage from the primary settling tank chamber is directed through an overflow to the bioreactor chamber, where, together with the activated sludge, it is subjected to intensive aeration with compressed air. Thanks to this, activated sludge can decompose pollutants found in sewage into simple substances (biological treatment). Then, the purified sewage flows to the secondary settling tank, where the purified sewage is separated from the activated sludge suspension. Purified and clarified sewage flows from the treatment plant to the receiver through a special overflow, which prevents excessive sludge from entering the outflow.

The technological parameters of the wastewater treatment process in an activated sludge treatment plant (such as the sewage retention time in the bioreactor, the substrate load of the activated sludge and the amount of air supplied to the system by the blower) guarantee the achievement of the required concentrations of BOD5 and COD in the treated sewage. The operating parameters of secondary settling tanks, determined by detention times, surface hydraulic loads and suspension loads, ensure the ability to achieve the required suspension concentration.

DRAINAGE DRAINAGE

Among sewage treatment processes, the most popular are sewage treatment plants that utilize pre-treated sewage in the ground. The introduction of sewage into the ground is achieved through appropriately selected seepage drainage. A sewage treatment plant with seepage drainage most often treats sewage discharged from single-family houses located in scattered suburban developments, rural farms or small production plants. The sewage treatment plant is virtually maintenance-free - condition check, serwis should take place every 6 months, sludge level control - every 12 months.

Domestic and domestic sewage is conveyed to the septic tank, where sedimentation of solids, flotation of fats and fermentation of accumulated organic parts carried by the sewage system take place. As a result of anaerobic processes, foam and a skin are formed here. Partially treated sewage flows through filtr cleaning agent, expanded clay and are directed to the separation well, which, thanks to its design, ensures their even distribution to the drainage threads and to the seepage bed, where the final biological treatment process takes place with the participation of aerobic and anaerobic bacteria. Sewage infiltrated using perforated pipes percolates through the soil layers, where the process of biological decomposition takes place. The aeration and ventilation system of the system operates thanks to the gravitational air flow resulting from the pressure difference between the aeration chimneys and the internal sewage vent outlet, which is led e.g. above the building's roof.

Summation

There are many different types of wastewater treatment plants available on the market, each offering unique benefits. The choice of an appropriate sewage treatment system depends on many factors, including the specific local conditions, investor requirements, environmental conditions and financial possibilities.

See our solutions for neutralizing water and sewage: https://navotech.com.pl/oferta/neutralizacja-wody-i-sciekow/

In our article, we emphasized that each system has its own unique advantages and limitations, and the decision should be made after careful analysis and consultation with experts. Please contact us if you have any questions or require further information.

Author: M.Sc. Eng. Adam Głogowski