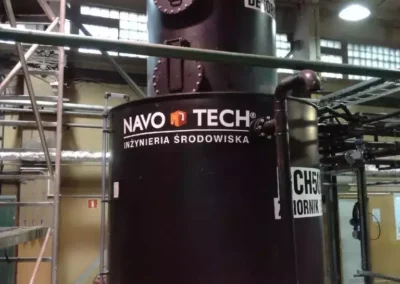

Desorbers, aeration towers

A desorber is a device used in some water treatment systems.

It is a non-pressurized device, consisting of a column (aeration tower) and a tank of appropriate dimensions (matched to individual needs).

In some installations where the collection of treated water is not necessary directly at the treatment site, only aeration towers are used, which are connected to the pumping system of the installation and the treated water is stored in separate tanks or fed directly to the network.

Desorber (aeration tower) uses counter-current flow of water and air: a spray nozzle is installed on the pipe supplying the medium to the desorber in the upper part of the tower, which is designed to disperse the water stream over the entire surface of the deposits inside the tower.

In the counter-current to the flowing water, the air moves, which blows the water retained on the beds of the tower. Air flow can be forced (blower) or gravitational.

The treated water is discharged through the stub pipe installed in the lower part of the tower to the storage tank or to the installation.

Desorber (aeration tower) is entirely made of corrosion-resistant materials: stainless/acid-proof steel and/or plastic.

The body of the tower usually consists of several segments to facilitate disassembly and cleaning of the bed.

The inspection/revision hole allows you to keep track of the cleanliness of the inside of the device.

Non-pressure aeration (oxygenation) of water before iron and manganese removal stations.

Removal of dissolved gases from water (min. CO2, H2S, NH3)

Iron removal of water

INFORMATION MATERIALS

Desorber, otherwise an aeration tower, is a device that uses a counter-current flow of water and air to treat water. In the upper part of the tower there is a spray nozzle that disperses the stream of water over the entire surface of the beds inside the tower. The air moves in the opposite direction to the downflowing water, blowing away water trapped on the tower beds. The air flow can be forced (using a blower) or gravitational. The treated water is then discharged to a storage tank or to the system via a spigot installed at the bottom of the tower.

Application: Desorbers are used in industry for water treatment. Thanks to the countercurrent flow of water and air, they enable effective cleaning water purification from various pollutants.

Action: The operation of the desorber is based on the use of a countercurrent flow of water and air. The water is sprayed at the top of the tower and then flows down, where it is blown with air. Air can be supplied by gravity or by blower. After flowing through the tower, the water is purified and ready for further use.